How To Make An Engagement Ring: 11 Steps to Craft a Stunning Diamond Engagement Ring

Have you ever wondered about the process behind making an engagement ring?

The craft of bespoke jewellery making is a complex and ancient one, taking years to master, a fine eye and surgical precision.

These days, many rings from larger companies and so-called luxury engagement ring brands are made in factories. However, to create the finest unique engagement rings, London-based Simon Wright uses a blend of modern design technology like Computer Aided Design (CAD) and 3D printing with artisanal techniques that haven’t changed in centuries.

Here is a sneak peek into the ring making process and the work that goes into creating your beautiful, one-of-a-kind, Simon Wright engagement ring.

1. Selecting the centre stone

Not all diamonds are created equal. You’ve probably heard of diamonds being graded on their characteristics like cut, colour and clarity. But people are often surprised to learn that diamond certificates are simply a grader’s opinion, and may not always accurately reflect the quality or brilliance of the stone. At Simon Wright, we always check our diamonds to make sure they’re of the quality the certificate suggests, and of a quality that we are happy to show to you when offering advice on choosing the perfect diamond for your ring.

Our clients often ask us what carat diamond they should choose when making an engagement ring. But as you’ve probably heard before, it’s not always the size that counts.

We work with our customers to select the most beautiful stone for their budget. The natural angles and features of a diamond can often mean it has a sparkle that ‘outshines’ its grade, so looking at the stone in person is an important part of the process. We want you to be happy with the stone you select, rather than experience the hard sell and buy something you end up having second thoughts about.

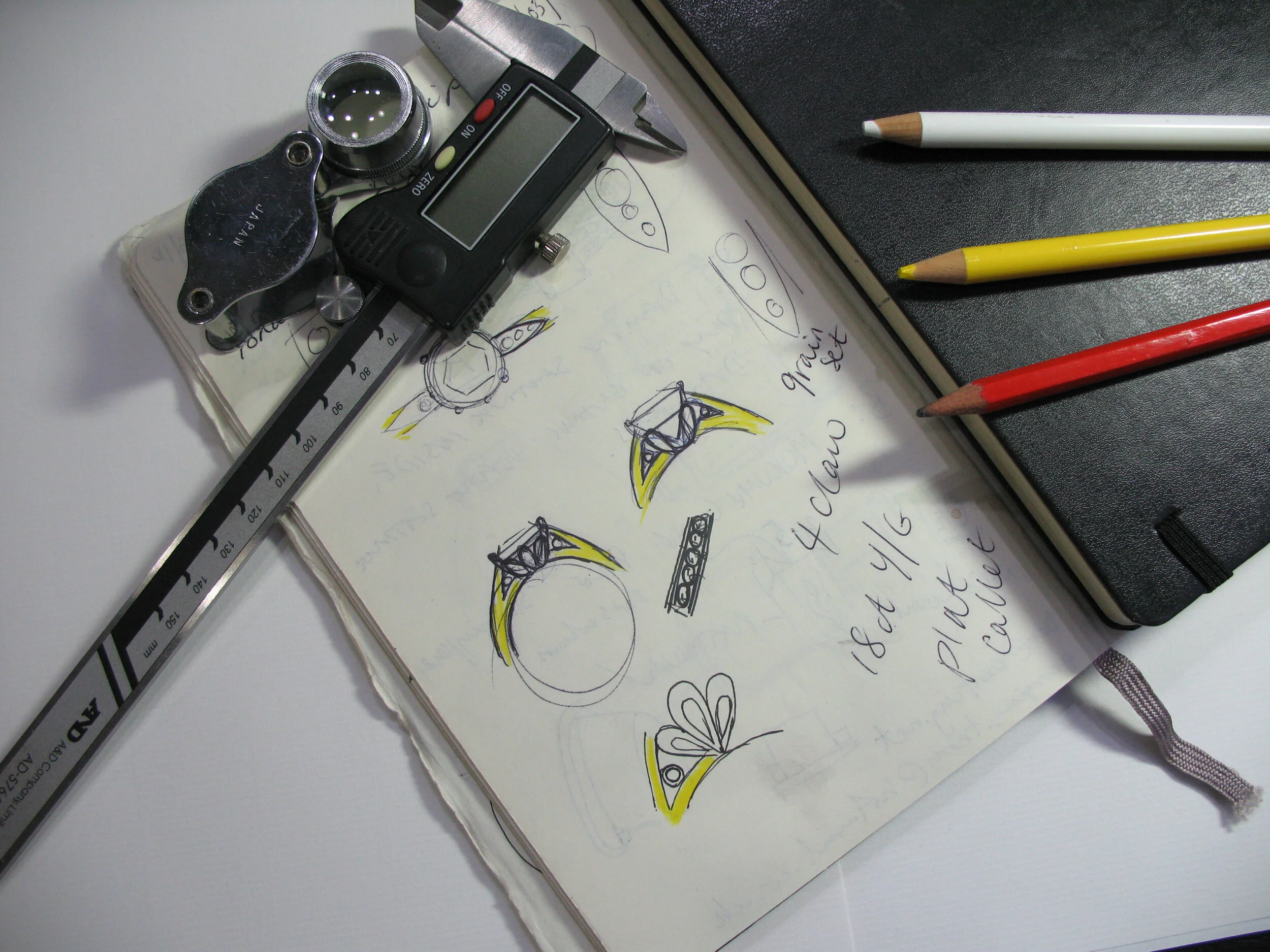

2. Creating a diamond ring design

This is where you see your ring begins to come to life! Your engagement ring setting is what shows off your diamond, or other precious stones, to the best effect. We work with our clients during the ring making process to create a ring design that meets their specifications, while still maintaining the durability needed for surviving being worn every day. After all, when you’re designing and making an engagement ring, you want it to perfectly align with your taste and style as well as lasting the rigours of modern life (Zoom meetings don’t count).

We use a combination of hand sketches and Computer Aided Design, which allows you to see the ring from a variety of angles, so you can make sure that every detail is right before we start working with expensive precious metals.

After the design is finalised, we use a 3D printer to create a resin model of your ring, which you can try on with the stones popped into the model.

3. Castings

The Computer Aided Design models are then printed again and are sent off to a casting company who make moulds of the models, and then cast them in precious metal. The rough pieces then come back to the workshop to be refined and crafted into the shining ring you (or your partner) will end up wearing.

We don’t do the casting in our workshop, as casting requires the metal to be heated to melting point using highly specialised equipment, and there’s a whole lot of mess!

4. Filing

Jewellers refer to the band of a ring as the ‘shank’ and the bits that hold the stones as the ‘settings’ or ’collets’. Once the rough pieces come back from the caster, we file the parts by hand so that they allfit together, and create a pleasing shape.

This work requires a highly practised hand and exceptional attention to detail. Accuracy to within a tenth of a millimetre is considered acceptable for a skilled jeweller, so no going out on the beers on a school night!

Did you know? All the filings that are produced during the ring making process (known in the trade as ‘lemel’) are kept in a leather apron suspended under the bench. They are later melted down and can be usedto make claws, jump rings (loops) and welding wire for the laser welder. We jewellers think we were doing zero waste before it was cool.

5. Soldering

Once all of the parts are filed and accurately fitting, they are soldered together using a blowtorch.

The solder will be either gold or platinum. It must be a different alloy to the ring parts, which gives it a lower melting temperature. Otherwise, everything would melt together (see: beers on a school night ☺)! The solder flows between the parts, making a solid join.

This can be the most challenging and stressful part of the ring making process, as both surfaces must be heated to a similar temperature. The jeweller judges the temperature by watching the colour of the metal as it heats up, and adjusts where to put the flame accordingly.

Time for a stiff drink (at last!) once this part of the process is complete, and the ring is still intact!

6. Hammering

Many people don’t associate fine jewellery with the kinds of tools you would find in your home garage, but all rings are hammered into that perfectly round shape that fits your finger so well.

We use a steel spike, called a mandrel, which helps to achieve a precise round shape, as well as making the ring the correct finger size, measured against the markings on the mandrel.

Hammering also hardens the metal, making it more durable.

When our clients first ask us about making an engagement ring, finger size is always one of the issues that are raised, especially how to secretly find out your partner’s ring size! If in doubt, why not check out our handy free ring size chart.

7. Post solder filing

Once the diamond setting has been soldered and hammered to shape, we bring the file out once more, to remove any excess metal, ensure the joins are seamless and there are no visible hammer marks.

So if you’ve ever wondered what to look for in a bespoke engagement ring, the quality of the joins and smoothness of the finished setting will tell you a lot about the quality of the craftsmanship, and the time and effort that went into perfecting your piece.

8. Emery paper

That might sound like a lot of steps so far, but it’s important that when you leave our studio with your ring, that it looks and feels every bit as perfect as you’d hoped it would be.e.

So, next, we pull out the emery paper, almost exactly the same thing you would use to manicure your nails.

This gives a more refined finish, before we polish the ring to give it that glittering shine!

9. Polishing

Polishing is one of the last, and also one of the trickiest steps of the bespoke engagement ring process. Polishing takes place using a special motor with a stitched cotton mop. If not done correctly, the ring can get caught and be damaged, or the jeweller can be injured, so a lot of skill is required.

We use two separate compounds to achieve the right finish during the ring making process. First, a cutting compound, which refines any remaining scratches from the emery paper. Then, we use a polishing compound to buff to a mirror finish, a skill which can take a long time to acquire, as some materials are particularly challenging to polish to this level of shine.

Today, the compounds we use are synthetic, but once upon a time, the cutting compound was made from animal fat and crushed emery stone, and the polishing compound was animal fat mixed with rust. Sometimes living in the 21st century is a good thing!

10. Setting

The final hands-on step is completing the setting for your unique engagement ring. The claws are pushed over the stone by hand, which requires some strength, as the ring is secured purely by force, no glue! Claws are made long at first to provide leverage and then trimmed down and smoothed.

11. A final once-over

We give every ring a final check-over and then another polish, making sure it looks perfect and has maximum sparkle when you collect it from our studio.

So how long does it take to create a hand-finished bespoke diamond engagement ring? Once the design is finalised, you can usually expect your ring to be ready in about three to four weeks. It depends on the design, though. Something more complicated can take a bit longer.

We are sometimes asked if it’s possible to make your own engagement ring. We love our clients to be involved in the design process, but if you’ve ever been curious about the work that goes into the creation of a piece of fine jewellery, you might have now realised that it in fact takes a great deal of skill, experience, and even a little risk!

If you are looking for an alternative to a diamond engagement ring, we can certainly help you in choosing the right gemstone for you. Teal sapphire engagement rings, vintage reproduction engagement rings and ruby cluster engagement rings are hugely popular these days. The choices are limitless!

Now you know how to make an engagement ring, why not start your bespoke engagement ring journey today? If you’d like to ask about working with us in making an engagement ring for you, or want to find out more about what to look for in an engagement ring, please get in touch. As you can tell, we love talking about all things jewellery!

Be sure to follow our Instagram page to see some of our latest creations, including teal sapphire engagement rings, bespoke earrings and a host of reproduction vintage jewellery.

Simon Wright is a highly respected jeweller whose precision, artistry, and dedication to craftsmanship have defined his career for over three decades. Known for his meticulous attention to detail and ability to create meaningful, exquisitely made pieces, he has earned recognition not only from clients but also within the wider industry. Simon has contributed to the prestigious Goldsmiths’ Craftsmanship & Design Awards as a judge, supporting innovation in design, and has trained apprentices who have gone on to build successful careers, cementing his reputation as both a master craftsman and a mentor within the luxury jewellery world.

Contact us today to

schedule an appointment

Start your bespoke engagement ring journey today